by Anna Brotzer, Senior Marketing Manager at Hitex, and Thomas Schütz, CEO at PROTOS Software GmbH.

Shifting testing to the development phase allows potential issues to be addressed as they arise.

Motor control systems drive many embedded applications, yet late-stage testing can be costly. Early testing ensures reliability and efficiency.

The importance of early testing

Early testing in motor control projects can save significant time and resources. Traditional testing methods rely heavily on system tests conducted at the final stages of development. These tests, while thorough, are often too late to catch issues that could have been addressed earlier. By shifting some of this testing to the development phase, developers can catch and address potential issues as they arise.

For instance, consider the typical development process of an embedded system. Initially, you might start with an evaluation board, configure some drivers, and try them out. Then you move on to programming hardware- related software components such as motor controllers and battery control systems. By the time you integrate these components into a complete application and move to the actual hardware, many potential issues might have been overlooked. By focusing on early testing, you can identify and fix these issues before they escalate.

Building and running tests

Developers need a test environment that mirrors real-world conditions as closely as possible. This environment allows for the development and testing of both software and its integration with hardware.

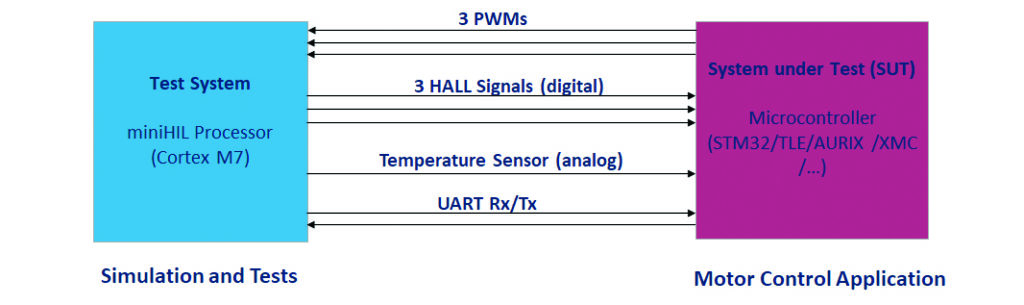

One effective method is to use hardware-in-the-loop (HIL) testing. HIL setups simulate the hardware environment, enabling developers to test their software thoroughly without the need for physical hardware. Three steps to build effective tests are as follows:

#1: Set up the simulation environment:

Use an evaluation board that is compatible with the microcontroller. Connect the board to a simulation system that replicates motor behaviors and sensor inputs.

Example: In a project involving a DC motor with a spring reset, the plant simulation can run at a frequency between 1 and 20kHz. The position sensor can be simulated as an analog signal to reflect the motor’s position, speed, or spring force.

#2: Develop test cases:

Design test cases that cover a wide range of scenarios, including edge cases and failure modes. Automate these test cases to

run with every code change to ensure continuous verification.

Example: Consider a test case where you need to simulate the motor control system’s response to a temperature error. The test

case would change the simulated temperature value and verify if the motor control system correctly handles the temperature increase or decrease.

#3: Integrate continuous testing:

Use continuous integration (CI) pipelines to automatically build, test, and deploy code changes. Ensure that every commit triggers a suite of automated tests, providing quick feedback to developers.

Automating test execution

Automating test execution can drastically reduce the time required for testing. By using a CI pipeline, developers can ensure that tests

run automatically with every code change. This setup provides immediate feedback, allowing developers to quickly identify and fix issues.

Automated testing offers several advantages. One of the primary benefits is speed, as automated tests run much faster than manual ones, allowing for quicker feedback to developers. Additionally, automated tests are consistent; they run the same way every time, which helps to reduce the chances of human error.

Coverage is also significantly improved with automated testing. Automated tests can cover a broader range of scenarios and edge cases than manual tests. For instance, in a motor control system, automated tests can simulate various operational states and error conditions, such as temperature fluctuations or motor faults, that would be cumbersome and time-consuming to replicate manually. This comprehensive coverage ensures that the system is thoroughly tested and robust against different potential issues.

Case study

Consider a motor control system for an oil pump, a safety-critical application used in various industries. Traditional testing methods

involved using a climate chamber to test the system across different temperatures. This method was slow and prone to interruptions, leading to incomplete test coverage.

Simulation setup:

In our method, only the microcontroller and its software stack were placed in the test environment. The rest of the system, including sensors, actuators, and even the motor, was simulated. For example, instead of using a climate chamber to test temperature effects on the motor control system, we simulated temperature variations digitally. This allowed us to test conditions like -40°C to +40°C in minutes rather than hours.

Test automation:

We automated the tests to run on every code commit. This transition from manual to automated testing drastically reduced the testing time. For instance, what used to take approximately 30 days for a complete testing cycle now takes just 50 minutes. By automating the HIL tests, developers receive immediate feedback on every code change, ensuring that any new bugs are caught early.

Results:

Our automated setup was able to test the system across 300 relevant states, covering all possible failure modes. This included simulating various operational states such as motor speed changes, temperature-induced shutdowns, and error conditions. The automated tests provided consistent and reliable results, ensuring that the motor control system could handle real-world conditions effectively.

By incorporating both the setup and simulation methodologies, we achieved a faster, more reliable testing process that ensures the motor control system is robust and ready for deployment.

Common pitfalls

Inaccurate Simulations: Ensure that your simulation models are as close to the real-world scenarios as possible. Regularly validate and update your models based on real-world data.

Overlooking Edge Cases: Design test cases to cover all possible scenarios, including rare and extreme conditions. Automated tools can help in systematically generating and running these tests.

Managing Test Automation Scripts: Maintain a clean and well-documented codebase for your test scripts. Use version control systems to manage changes and ensure consistency.

Conclusion

Early testing in motor control projects is crucial for efficient development. By integrating testing into the development process, using simulated environments and automating test execution, developers can save time and resources while ensuring robust and reliable systems.