E-caps are great components for smoothing the output of a DC-DC converter

Ryan Messina – Technical Sales Group, Technical Applications Engineer at KYOCERA AVX

A DC-DC converter is an electronic circuit or device that converts a source of direct current (DC) from one voltage level to another. Such converters can be found in almost all electronic devices. As power systems become more and more intricate, DC-DC converters play an increasingly pivotal role in modern power management systems.

There are many types of DC-DC converters, but the most widely used are boost converters (stepping voltage up from a lower voltage source), buck converters (stepping voltage down from a higher voltage source) or a combination of the two, as seen in buck-boost converters.

With the rise in the electrification of vehicles, advanced avionics systems in modern aircraft, renewable energy integration, and telecommunications, DC-DC converters are an essential component of the advancement in electronics worldwide. One consideration is that DC-DC converters necessitate the use of very large capacitance values at specific nodes to smooth the output. This is where aluminum electrolytic capacitors earn their keep.

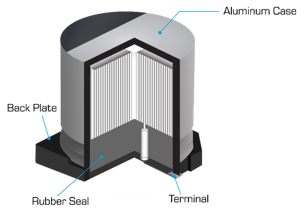

Aluminum electrolytic capacitors, or e-caps, have been around for quite some time and fill a very specific need: bulk capacitance. E-caps come in a variety of form factors, terminations, and technologies. The three technologies are comprised of wet, polymer, and hybrid, each with its own inherent pros and cons.

The traditional wet e-cap boasts the highest capacitance and voltage capabilities with the lowest direct current leakage (DCL) but, on average, has a higher equivalent series resistance (ESR). The polymer e-cap has the lowest ESR of the three technologies but trades a low ESR for a higher DCL. The hybrid e-cap has a balance of low ESR and low DCL.

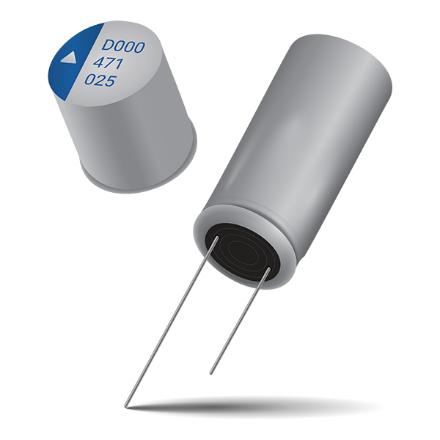

Wet e-caps, in most cases, will be the cheaper option and more readily available, but they do have a slight disadvantage in extreme temperature applications, as the wet electrolyte can evaporate, and they have higher ESR at very low temperatures. The hybrid e-cap can operate in higher temperature applications because it is comprised of both wet and polymer technologies, but it is generally a more expensive part. The polymer e-cap works very well in variable temperature applications but does not have the capability to reform oxide layers because it is a solid. All three of these e-cap technologies come in either radial leaded, V-chip (i.e., surface mount technology (SMT)), or snap-in terminations.

To summarize, e-caps are a great component in smoothing the output of a DC-DC converter. As a designer, it is best to choose low ESR parts with a high capacitance in the smallest case sizes. Most manufacturers offer all the technologies listed above but may have different termination and capacitance offerings. For Kyocera AVX, the V-Chips, or SMT e-caps, are practical for prototyping or throwing on a test board for smaller power/lower current supplies. The radial e-caps should be utilized when there is a need to increase the power for a specific application (as the case sizes inherently increase with the radial package). Snap-ins are usually limited to high ripple current and high-power applications.