In addition to ESD protection, MLVs also offer EMI suppression.

By Daniel West, Lead Technical Applications Engineer, KYOCERA AVX Components.

A Multi-Layer Varistor (MLV) functions as a circuit protection device, but also offers EMI suppression that may be little known. The MLV construction and material set are very similar to MLCC (Multi-Layer Ceramic Capacitor) processes and naturally have an inherent capacitance. To achieve the varistor (i.e., variable resistor) quality, MLVs have a zinc oxide barrier around each grain of ceramic (typically Class II ceramic), which provides the semiconductor property. At a given voltage, the barrier will break down and become increasingly conductive as voltage rises, effectively shunting current to ground and protecting loads (typically sensitive ICs) in the event of transient overvoltage; electrostatic discharge (ESD) being a common source. For most of the time, however, transients are not present in a circuit, and this is when the secondary function of EMC capacitor starts to

be apparent for MLVs.

Automotive electronics provide a good context to discuss the dual component benefit of MLVs. EMC and circuit protection are paramount in these applications because of the large number of ICs and transient overvoltage sources like inductive switching, alternator switching (Load Dump), Start/Stop, and battery charging (Jump Start), all in addition to ESD. A traditional EMC/ circuit protection solution for a communications bus would include a bi-directional TVS (Transient Voltage Suppression) diode or two unidirectional TVS diodes with at least one EMI filtering capacitor in each case.

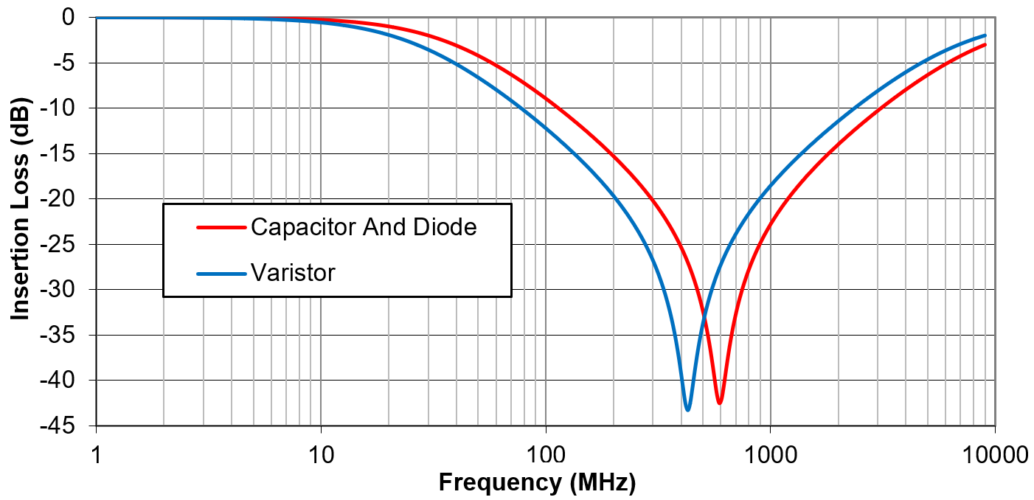

MLVs obviate the need for all these devices so long as the frequency response is comparable or superior to the TVS diode + EMC cap combo. The good thing is that it’s reasonably easy to design MLVs for a specific capacitance value. To be fair, it is difficult to achieve low capacitance values and maintain equivalent transient energy dissipation, but there are sub-picofarad MLVs from Kyocera AVX in EIA 0402 sizes for size-constrained high-speed communication applications where capacitive loading is undesirable. Other MLV innovations include 175°C devices and flexible terminations. Flexible or soft terminations are certainly not a recent innovation for SMT components, but electroplating terminations can prove to be a challenge for MLVs because the body is a varistor, and this is where the innovation really lies. There are feedthrough filter MLVs and stacked MLVs in a radial leaded package that are ideal for motor applications for broad spectrum EMI filtering.

MLVs are many times crossed to TVS diodes based solely on clamping voltages, but this comparison isn’t always apples-to- apples, especially from a BOM point-of-view. For example, TVS diodes have extremely low capacitance values and will likely require an EMC cap (or caps) in parallel for signal lines that need EMI filtering. By comparison, the MLV arrives with a free EMC capacitor.